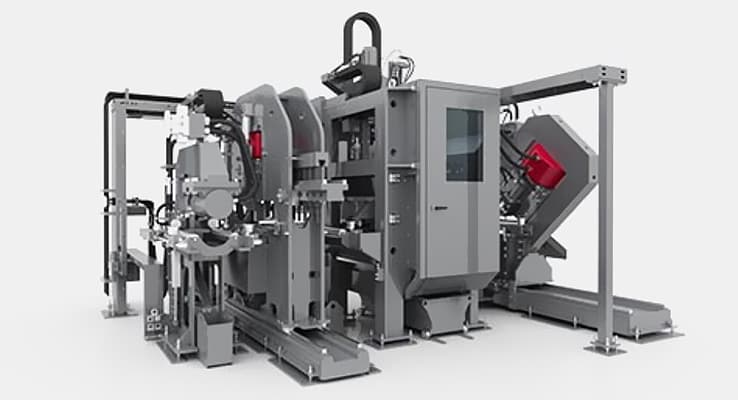

Beam Layout Welding Limitations

Gulf States Saw & Machinery Co. have established themselves as the global leaders in steel fabrication technology. Beam Layout Welding machines allow steel fabricators to maintain a competitive edge in the industry and maximize tonnage.